Before writing about Production Engineering, Process Engineering, Quality Engineering, the relationship between these three fields, and how we apply them in the technology field (systems development), I will begin by briefly explaining the reasons that led me to write about this subject (in other words, “writing about the reasons for writing”).

Establishing a connection between Production, Process, and Quality Engineering should not—at least in my view—be difficult for professionals who work in these areas. Applying these disciplines in the technology field—with or without adaptations—shouldn’t be either. However, the lack of discussion on the correlation between the engineering disciplines and the origin of some tools, along with observing attempts to solve problems in one area without considering the others, made me wonder whether the connection among them is as visible (and clear) to others as I believe it should be. And this doubt bothers me. So, because of this discomfort, I decided to write about it—illustrating when necessary.

My intention is to publish texts on this site following a logical sequence. Therefore, I believe the most appropriate starting point is to align some terms and definitions, while also illustrating the relationship between the topics at a surface level (with further depth to come in later publications).

Defining the Terms

Starting with a few brief and simple definitions:

- Engineering: (1) The science, technique, and art of constructing large-scale works by applying mathematical and physical science principles. (2) The application of scientific or empirical methods to the use of natural resources for the benefit of humankind.

- Quality: (1) A set of characteristics inherent in something that allow it to at least meet the specifications and expectations of its users. (2) The sum of all efforts made by an organization to satisfy the customer.

And now, a few compound definitions:

- Production Engineering: “Production Engineering is responsible for designing, implementing, operating, improving, and maintaining integrated production systems for goods and services involving people, materials, technology, information, and energy. It is also responsible for specifying, predicting, and evaluating the outcomes of these systems using knowledge from mathematics, physics, and social sciences, along with engineering analysis and design principles.” (based on definitions from the International Institute of Industrial Engineering – IIIE)

- Process Engineering: Derived from Production Engineering and used across multiple sectors, Process Engineering aims to manage and map business processes, identifying improvement points and redesigning processes with a focus on continuous improvement (more efficiency, higher quality, better customer experience, and cost reduction).

- Quality Engineering: A set of methodologies, processes, and principles that help an organization improve its business processes in order to achieve a certain level of quality in its products or services.

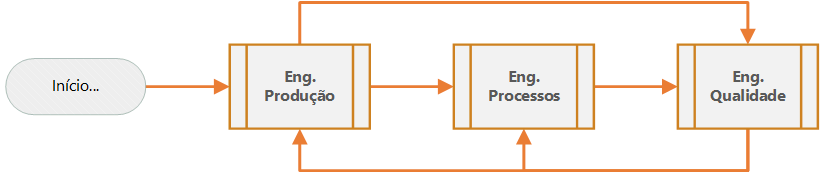

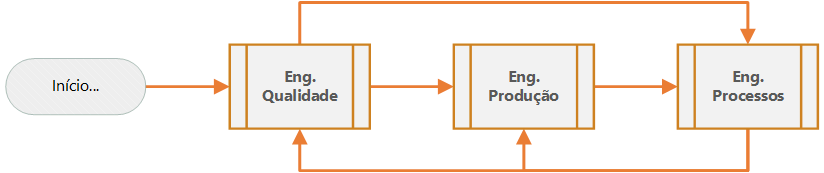

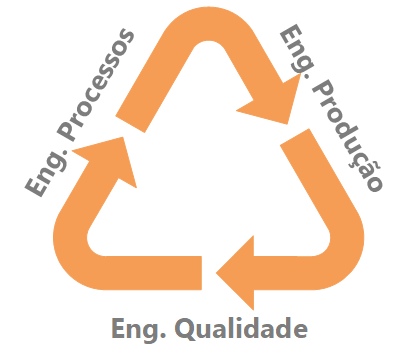

Relating the engineering disciplines

Taking Production Engineering as a starting point (not that it is necessarily the first of the engineering disciplines), the responsibilities mentioned (“predict,” “design,” “maintain,” “evaluate,” and “improve”) naturally lead to questions that the discipline itself must answer (“how to predict?”, “how to design?”, “how to maintain?”, “how to evaluate?”, and “how to improve?”).

However, over time—whether that time refers to the “micro-history” of an organization or the “macro-history” of humanity—the “old answers to old questions” may no longer fully or adequately meet the needs (of an organization or of the field as a whole), and deeper investigation, new approaches, or even new answers to emerging questions become necessary. This is when the triggers are pulled for the development of a specialization (deepening of an existing field), the emergence of a new field (such as Process Engineering, which originates from Production Engineering), or the involvement of other areas (for instance, when an organization with a “quality department” creates a “process department”—or vice versa).

And just as Civil Engineering—for example—proves essential to the construction of the physical infrastructure where Production Engineering carries out its role (considering the “micro” level of the organization), Process Engineering—derived from Production Engineering—starts providing Production Engineering (on a “macro” level as well) with new answers, approaches, and tools that make the development of organizational activities more efficient.

To better understand how these disciplines intersect, overlap, or go deeper into one another, follow the articles published here (in fact, for at least one of these areas, we can find not only articles but even “manuscripts” on the topic).

And regarding the technology field—how we find or apply the other engineering disciplines within it—I will write about that further ahead.